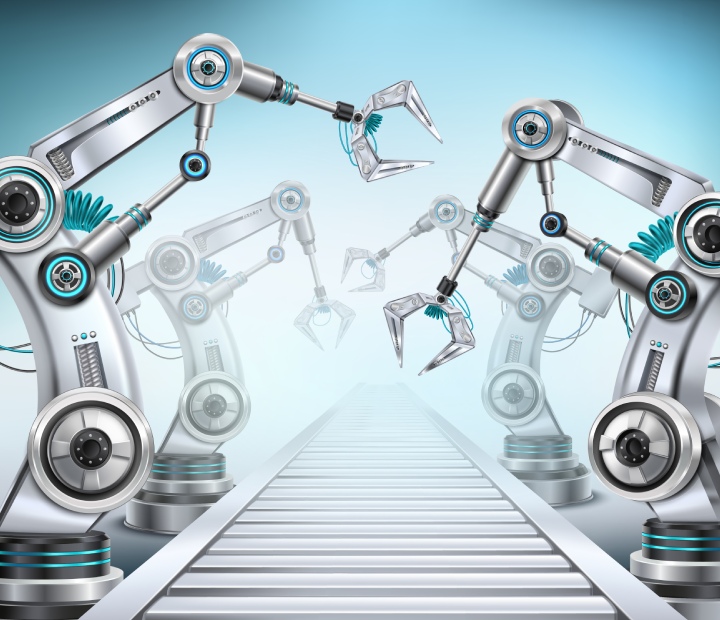

With the advent of automated handling systems, manufacturing facilities now take advantage of increased throughput and reduced expenses. A conveyor is undoubtedly the most popular equipment of this kind offering immense opportunities of integrated automation to industries. It is especially useful in areas involving the movement of items from one location to another, making the procedure not as strenuous as it was with manual handling. To make it clear, reduced physical labor and effective time management are the features all types of conveyor systems have in common.

A handling system is synonymous with numerous benefits in terms of efficiency, safety, and reduced downtime. Due to the ability to convey items of all weights, sizes, and shapes, different types of conveyor solutions are practically applied in automotive, aerospace, mining, food processing, pharmaceutical, distribution, packaging, and warehousing industries.

They can be easily installed almost at any location while ensuring the adequate flow of materials to the intended destination. Moreover, these machines provide considerable flexibility when used at a production site. That is why they open up the whole new world of opportunities for internal logistics.

Depending on the loading method, required conveying speed, temperature conditions, and overall dimensions of items intended to be moved, various conveyor types may be used. Traditionally, handling systems differ in the way of functioning and fall into:

These systems do not use any power sources to convey items but rely on the natural force of gravity only. Generally, non-powered units are used for sorting and truck loading operations. They often feature detachable modules, allowing to modify the handling system according to the industrial needs.

Non-powered conveyors are available in several options that differ in a bed type. Today, the most common systems are skatewheel and roller ones. Thanks to the independently moving wheels, the first type is mainly used with curved sections. Roller conveyors, in their turn, provide convenience for a working surface.

It’s clear that powered units use some motor that enables them to handle materials. Such systems are considered to be the most effective types of conveyor solutions as they successfully deal with bulky items without human intervention. While providing steady speed and surface, powered equipment minimizes the risk of box displacement and roll-over.

Powered conveyors may be divided into belt and roller systems, which are highly advantageous for accumulating items at the required location. They differ in the drive type, power requirements, load capacity, and some other configurations. Also, motor-based spiral machines are often used for vertical conveying.

When it comes to heavy-duty applications or oversized material movement, these units prove to be the most practical solutions. Both chain-driven conveyors and roller pallet-handing systems feature wider and more durable sections that allow for handling loads of up to hundreds of pounds. Therefore, they are extremely useful for distribution centers, manufacturing sites, and other facilities involving the transportation of heavy items.

To sum up, the conveyor market has grown enough to meet the needs of all end users by providing them with a wide range of products. Remember, the right material-handling equipment is a vital choice that directly affects the effectiveness and success of your activity.